Product Description

Product Description

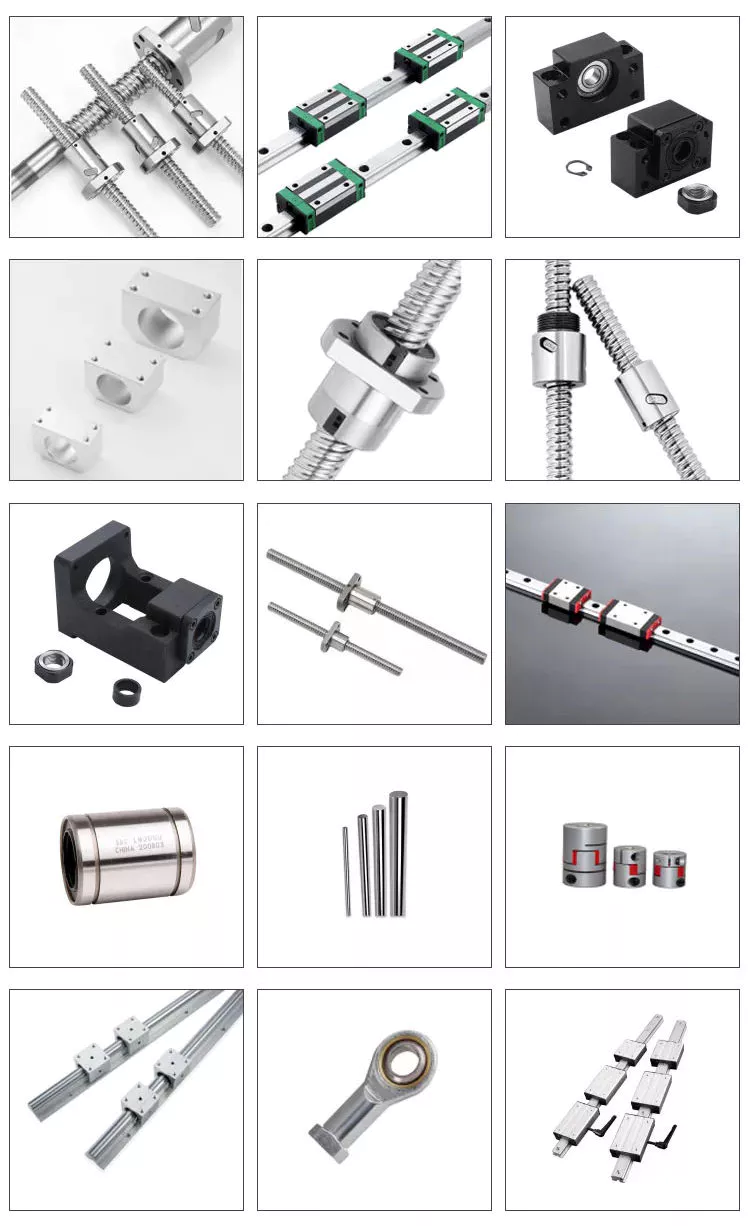

Detailed Photos

Packaging & Shipping

Company Profile

Our Advantages

| List Of Hydraulic Parts | |

| KOMATSO EXCAVATOR SERIES | |

| 1 | HPV35(PC60) Hydraulic parts |

| 2 | HPV55(PC120) Hydraulic parts |

| 3 | HPV90(PC200-3) Hydraulic parts |

| 4 | HPV90(PC200-5) Hydraulic parts |

| 5 | HPV95(PC200-6,PC120-6) Hydraulic parts |

| 6 | HPV132(PC300-7,400-6) Hydraulic parts |

| 7 | HPV160(PC300/400-3/5)Hydraulic parts |

| 8 | HPV135 Hydraulic parts |

| 9 | PC30UU Hydraulic parts |

| 10 | PC40-8 MAIN PUMP Hydraulic parts |

| 11 | PC50 (PC55/56) Hydraulic parts |

| 12 | PC60-7 (HPV75)MAIN PUMP Hydraulic parts |

| 13 | PC160 Hydraulic parts |

| 14 | PC200-2 MAIN PUMP Hydraulic parts |

| 15 | PC200-8 MAIN PUMP/PC240-8 MAIN PUMP Hydraulic parts |

| 16 | PC320 Hydraulic parts |

| 17 | PC360-7(PC300-7) MAIN PUMP Hydraulic parts |

| 18 | PC400-7 MAIN PUMP Hydraulic parts |

| 19 | PC1250 MAIN PUMP Hydraulic parts |

| 20 | PC45R-8 SWING MOTOR Hydraulic parts |

| 21 | PC60-6 SWING MOTOR Hydraulic parts |

| 22 | PC60-7 SWING MOTOR Hydraulic parts |

| 23 | PC120-6 SWING MOTOR Hydraulic parts |

| 24 | PC200-6 SWING MOTOR /LMF45 Hydraulic parts |

| 25 | PC220-7 SWING MOTOR Hydraulic parts |

| 26 | PC450 SWING MOTOR Hydraulic parts |

| 27 | PC650 SWING MOTOR Hydraulic parts |

| 28 | PC200-7 TRAVEL MOTOR Hydraulic parts |

| 29 | PC400-7 TRAVEL MOTOR Hydraulic parts |

| 30 | HPV220-8 SWING MOTOR Hydraulic parts |

| 31 | PC650 SWING MOTOR Hydraulic parts |

| HITACHI SERIES | |

| 32 | HPV050 Hydraulic parts |

| 33 | HPV080 Hydraulic parts |

| 34 | ZX120-6 MAIN PUMP(HPK055) Hydraulic parts |

| 35 | HPV091(EX200-2/3,EX120-2 SINGLE PUMP) Hydraulic parts |

| 36 | HPV102(EX200-5/6) Hydraulic parts |

| 37 | HPV116(EX200-1) Hydraulic parts |

| 38 | HPV118 (ZX200-3,ZX270) MAIN PUMP Hydraulic parts |

| 39 | HPV125B(UH07,UH083) Hydraulic parts |

| 40 | HPV145(EX300-1/2/3)Hydraulic parts |

| 41 | EX400-5 MAIN PUMP Hydraulic parts |

| 42 | EX60-2/3 SWING MOTOR Hydraulic parts |

| 43 | EX105-2 MOTOR Hydraulic parts |

| 44 | EX120-2 SWING MOTOR Hydraulic partsV |

| 45 | EX120-5 SWING MOTOR(AP5S67) Hydraulic parts |

| 46 | ZAX120 SWING MOTOR Hydraulic parts |

| 47 | EM56 TRAVEL MOTOR Hydraulic parts |

| 48 | HMGC16(EX100-1 TRAVEL MOTOR) Hydraulic parts |

| 49 | HMGC32(EX200-1 TRAVEL MOTOR) Hydraulic parts |

| 50 | HMGC35(EX200-5 TRAVEL MOTOR) Hydraulic parts |

| 51 | EX550-3 TRAVEL MOTOR Hydraulic parts |

| 52 | HMGE36EA(ZX200 TRAVEL MOTOR) Hydraulic parts |

| 53 | HMF160 Hydraulic parts |

| 54 | ZX330-2 TRAVEL MOTOR Hydraulic parts |

| CATERPILLAR SERIES | |

| 55 | VRD63(CAT120) Hydraulic parts |

| 56 | SBS80(CAT312C)MAIN PUMP Hydraulic parts |

| 57 | E200B NEW DESIGN Hydraulic parts |

| 58 | AP-12 Hydraulic parts |

| 59 | AP-14(CAT325C) Hydraulic parts |

| 60 | CAT320C Hydraulic parts |

| 61 | SPK10/10(E200B) Hydraulic parts |

| 62 | SPV10/10(MS180)Hydraulic parts |

| 63 | CAT12G Hydraulic parts |

| 64 | CAT14G/16G Hydraulic parts |

| 65 | CAT215 Hydraulic parts |

| 66 | CAT245 Hydraulic parts |

| 67 | CAT330B TRAVEL MOTOR Hydraulic parts |

| 68 | PSV450(AP-12) TRAVEL MOTOR Hydraulic parts |

| 69 | CAT992 Hydraulic parts |

| 70 | CAT330C TRAVEL MOTOR Hydraulic parts |

| 71 | CAT385H Hydraulic parts |

| KYB SERIES | |

| 72 | PSVD2-16E Hydraulic parts |

| 73 | PSVD2-21C Hydraulic parts |

| 74 | PSVD2-21E(KYB)4T/SVD22 (KYB-4T) Hydraulic parts |

| 75 | KMF40 Hydraulic parts |

| 76 | KMF40-2 Hydraulic parts |

| 77 | KMF90(KPV90)PC200-1/2/3(SWING MOTOR ,TRAVEL MOTOR) Hydraulic parts |

| 78 | KMF105 Hydraulic parts |

| 79 | KYB33 Hydraulic parts |

| 80 | KYB36 Hydraulic parts |

| 81 | KYB37 Hydraulic parts |

| 82 | KYB87 Hydraulic parts |

| 83 | KYB90 Hydraulic parts |

| NACHI SERERIES | |

| 84 | PVD-2B-32L Hydraulic parts |

| 85 | PVD-2B-34 TRAVEL MOTOR Hydraulic parts |

| 86 | PVD-2B-34L MINITYPE EXCAVATOR MAIN PUMP Hydraulic parts |

| 87 | PVD-2B-36L/38/40 Hydraulic parts |

| 88 | PVD-2B-42 Hydraulic parts |

| 89 | PVD-2B-63 Hydraulic parts |

| 90 | PVD45 Hydraulic parts |

| 91 | NACHI 130 Hydraulic parts |

| 92 | PVK-2B-505 Hydraulic parts |

| 93 | BOB CAT 331 EXCAVATOR(SWING MOTOR) Hydraulic parts |

| 94 | BOB CAT337 TRAVEL MOTOR Hydraulic parts |

| TOSHIBA SERIES | |

| 95 | SG02 Hydraulic parts |

| 96 | SG571(MFB40) Hydraulic parts |

| 97 | SG04(MFB80) Hydraulic parts |

| 98 | SG08(MFB160) Hydraulic parts |

| 99 | SG12 Hydraulic parts |

| 100 | SG20(MFB250) Hydraulic parts |

| 101 | PVB92 (PVC90RC08 / PVC70R) Hydraulic parts |

| 102 | PV090 Hydraulic parts |

| 103 | PV092(PV080 INTERCHANGEABLE) Hydraulic parts |

| 104 | PSVS-90 Hydraulic parts |

| 105 | JIC SERIES |

| 106 | JMV-44/22 Hydraulic parts |

| 107 | JMV-53/34(6-8T TRAVEL MOTOR) Hydraulic parts |

| 108 | JMF-64 Hydraulic parts |

| 109 | JMV-147/95 Hydraulic parts |

| 110 | JMF-151-VBR(22SM1510117) Hydraulic parts |

| 111 | JMF-155 Hydraulic parts |

| LIEBHERR SERIES | |

| 112 | LPVD45 Hydraulic parts |

| 113 | LPVD64 Hydraulic parts |

| 114 | LPVD75 Hydraulic parts |

| 115 | LPVD90 Hydraulic parts |

| 116 | LPVD100 Hydraulic parts |

| 117 | LPVD100 NEW DESIGN Hydraulic parts |

| 118 | LPVD125 Hydraulic parts |

| 119 | LPVD125 NEW DESIGN Hydraulic parts |

| 120 | LPVD140 Hydraulic parts |

| 121 | LPVD250 Hydraulic parts |

| 122 | LPVD260 Hydraulic parts |

| KAWASAKI SERIES | |

| 123 | K3SP36C(SDV36)(8T MID-TYPE EXCAVATOR MAIN PUMP) Hydraulic parts |

| 124 | K3V63DT(K3V63BDT) Hydraulic parts |

| 125 | K3V112DT Hydraulic parts |

| 126 | K3V140DT Hydraulic parts |

| 127 | K3V180DT Hydraulic parts |

| 128 | K3V280 Hydraulic parts |

| 129 | K3VG280 Hydraulic parts |

| 130 | K3VG180 Hydraulic parts |

| 131 | K3VL45 Hydraulic parts |

| 132 | K5V80 Hydraulic parts |

| 133 | K5V140(DOOSAN 300-7)(DOOSAN 300-7) Hydraulic parts |

| 134 | K5V160 (HYUNDAI 300-6 MAIN PUMP) Hydraulic parts |

| 135 | K5V200(JAPAN 450/470,KOBELCO 470,CASE 480 MAIN PUMP) Hydraulic parts |

| 136 | K7V63 Hydraulic parts |

| 137 | NV64 Hydraulic parts |

| 138 | NV84 Hydraulic parts |

| 139 | NV111DT Hydraulic parts |

| 140 | NV137 Hydraulic parts |

| 141 | NV172 Hydraulic parts |

| 142 | NV270 Hydraulic parts |

| 143 | NX15 Hydraulic parts |

| 144 | NVK45(KOBELCO EXCAVATOR) Hydraulic parts |

| 145 | KVC925 Hydraulic parts |

| 146 | KVC930 Hydraulic parts |

| 147 | KVC932 Hydraulic parts |

| KAWASAKI SWING MOTOR SERIES | |

| 148 | M2X63 Hydraulic parts |

| 149 | M2X96(EX200-2) Hydraulic parts |

| 150 | M2X120 Hydraulic parts |

| 151 | M2X146(EX200-5) Hydraulic parts |

| 152 | M2X150/170(EX400) Hydraulic parts |

| 153 | M2X210(EX270/280/300) Hydraulic parts |

| 154 | M5X130(CAT320C) Hydraulic parts |

| 155 | M5X180 (KOBELCO 350-8 SWING MOTOR) Hydraulic parts |

| 156 | MX150 Hydraulic parts |

| 157 | MX173 Hydraulic parts |

| 158 | MX500 Hydraulic parts |

| 159 | MAG150 Hydraulic parts |

| 160 | MAG170 Hydraulic parts |

| 161 | LZV30 Hydraulic parts |

| 162 | LZV120 Hydraulic parts |

| 163 | LVWO60 Hydraulic parts |

| 164 | TM40VD TRAVEL MOTOR Hydraulic parts |

| REXROTH SERIES | |

| 165 | A4V40 Hydraulic parts |

| 166 | A4V56 Hydraulic parts |

| 167 | A4V71 Hydraulic parts |

| 168 | A4V125 Hydraulic parts |

| 169 | A4V250 Hydraulic parts |

| 170 | A4VFO28 Hydraulic parts |

| 171 | A4VSO40 Hydraulic parts |

| 172 | A4VSO45 Hydraulic parts |

| 173 | A4VSO71 Hydraulic parts |

| 174 | A4VSO125 Hydraulic parts |

| 175 | A4VSO180 Hydraulic parts |

| 176 | A4VSO250 Hydraulic parts |

| 177 | A4VSO355 Hydraulic parts |

| 178 | A4VSO500 Hydraulic parts |

| 179 | A4VF500/A4F500 Hydraulic parts |

| 180 | A4VG28(A4FO28) Hydraulic parts |

| 181 | A4VG40 Hydraulic parts |

| 182 | A4VG45 Hydraulic parts |

| 183 | A4VG50 Hydraulic parts |

| 184 | A4VG56 Hydraulic parts |

| 185 | A4VG71 Hydraulic parts |

| 186 | A4VTG71 Hydraulic parts |

| 187 | A4VG90(A4VT90HW/32R) Hydraulic parts |

| 188 | A4VHW90 Hydraulic parts |

| 189 | A4VTG90 CHARGE PUMP |

| 190 | A4VG125 |

| 191 | A4VG125 CHARGE PUMP |

| 192 | A4VG125 CHARGE PUMP SPARE PARTS |

| 193 | A4VG125 CHARGE PUMP(TANDEM A10VSO28) |

| 194 | A4VG125 CHARGE PUMP(OVERSIZE DESIGN) |

| 195 | A4VG140 Hydraulic parts |

| 196 | A4VG180 Hydraulic parts |

| 197 | A4VG250 Hydraulic parts |

| 198 | A10VSO16/18 Hydraulic parts |

| 199 | A10VSO28 Hydraulic parts |

| 200 | A10VSO45 Hydraulic parts |

| 201 | A10VO45/52 Hydraulic parts |

| 202 | A10VSO63/52 Hydraulic parts |

| 203 | A10VSO63/53 Hydraulic parts |

| 204 | A10VSO71 Hydraulic parts |

| 205 | A10VSO85 Hydraulic parts |

| 206 | A10VSO100 Hydraulic parts |

| 207 | A10VSO140 Hydraulic parts |

| 208 | A10VG18 Hydraulic parts |

| 209 | A10VG28 Hydraulic parts |

| 210 | A10VG45 Hydraulic parts |

| 211 | A10VG63 Hydraulic parts |

| 212 | A10V43 Hydraulic parts |

| 213 | A10V63 Hydraulic parts |

| 214 | A10VD40 Hydraulic parts |

| 215 | A10VD43 Hydraulic parts |

| 216 | A10VE43 Hydraulic parts |

| 217 | A10VEC60 Hydraulic parts |

| 218 | A10VSF28 Hydraulic parts |

| 219 | A11VO40 Hydraulic parts |

| 220 | A11VG35 Hydraulic parts |

| 221 | A11VG50 Hydraulic parts |

| 222 | A11VO60 Hydraulic parts |

| 223 | A11VO75 Hydraulic parts |

| 224 | A11VO95(A11V95) Hydraulic parts |

| 225 | A11V130 Hydraulic parts |

| 226 | A11V145 Hydraulic parts |

| 227 | A11V160 Hydraulic parts |

| 228 | A11V190/A11VLO190 Hydraulic parts |

| 229 | A11VO200 Hydraulic parts |

| 230 | A11VO250 Hydraulic parts |

| 231 | A11VLO260 Hydraulic parts |

| REXROTH BEND AXIS PUMP SERIES | |

| 232 | A2F5 Hydraulic parts |

| 233 | A2F12 Hydraulic parts |

| 234 | A2F23 Hydraulic parts |

| 235 | A2VK28 Hydraulic parts |

| 236 | 2VK28 Hydraulic parts |

| 237 | A2F28 Hydraulic parts |

| 238 | A2F55 Hydraulic parts |

| 239 | A2F80 Hydraulic parts |

| 240 | A2F107 Hydraulic parts |

| 241 | A2F160 Hydraulic parts |

| 242 | A2F200 Hydraulic parts |

| 243 | A2V225 Hydraulic parts |

| 244 | A2F250 Hydraulic parts |

| 245 | A2V500 Hydraulic parts |

| 246 | A2V915 Hydraulic parts |

| 247 | A2F355 Hydraulic parts |

| 248 | A2F500 Hydraulic parts |

| 249 | A2F1000 Hydraulic parts |

| 250 | A2FO10 Hydraulic parts |

| 251 | A2FO12 Hydraulic parts |

| 252 | A2FO16 Hydraulic parts |

| 253 | A2FO23 Hydraulic parts |

| 254 | A2FO28 Hydraulic parts |

| 255 | A2FO32 Hydraulic parts |

| 256 | A2FO45 Hydraulic parts |

| 257 | A2FO56 Hydraulic parts |

| 258 | A2FO63 Hydraulic parts |

| 259 | A2FO80 Hydraulic parts |

| 260 | A2FO90/A2FE90 Hydraulic parts |

| 261 | A2FO107 Hydraulic parts |

| 262 | A2FO125(A2FM125) Hydraulic parts |

| 263 | A2FO160 Hydraulic parts |

| 264 | A2FO180 Hydraulic parts |

| 265 | A2FO200 Hydraulic parts |

| 266 | A2FO250 Hydraulic parts |

| 267 | A2FO500 Hydraulic parts |

| 268 | A6V28 Hydraulic parts |

| 269 | A7V55/A8V55 Hydraulic parts |

| 270 | A7V58 Hydraulic parts |

| 271 | A7V80/A8V80 Hydraulic parts |

| 272 | A7V107/A8V107 Hydraulic parts |

| 273 | A7V160/A8V160 Hydraulic parts |

| 274 | A7V200 Hydraulic parts |

| 275 | A7V225 Hydraulic parts |

| 276 | A7V250 Hydraulic parts |

| 277 | A7V355 Hydraulic parts |

| 278 | A7V500 Hydraulic parts |

| 279 | A6VM/A7V1000 Hydraulic parts |

| 280 | A6VM/A7VO12 Hydraulic parts |

| 281 | A7VO28 Hydraulic parts |

| 282 | A7VO55 Hydraulic parts |

| 283 | A7VO80 Hydraulic parts |

| 284 | A7VO107 Hydraulic parts |

| 285 | A7VO160 Hydraulic parts |

| 286 | A6VM160 Hydraulic parts |

| 287 | A6VE160 Hydraulic parts |

| 288 | A6VM200 Hydraulic parts |

| 289 | A6VM500 Hydraulic parts |

| 290 | A7VO172 Hydraulic parts |

| 291 | A7VO200 Hydraulic parts |

| 292 | A7VO250 Hydraulic parts |

| 293 | A7VO355 Hydraulic parts |

| 294 | A7VO500 Hydraulic parts |

| REXROTH-UCHIDA SERIES | |

| 295 | A8VO55 Hydraulic parts |

| 296 | A8VO80 Hydraulic parts |

| 297 | A8VO80 6.3 SERIES Hydraulic parts |

| 298 | A8VO107(SUMITOMO 280) Hydraulic parts |

| 299 | A8VO140 Hydraulic parts |

| 300 | A8VO160 Hydraulic parts |

| 301 | A8VO200 Hydraulic parts |

| 302 | AP2D12(BOBCAT 331 MAIN PUMP) Hydraulic parts |

| 303 | AP2D16(CASE 35 EXCAVATOR) Hydraulic parts |

| 304 | AP2D18(IHISCE 45 EXCAVATOR MAIN PUMP) Hydraulic parts |

| 305 | AP2D21 Hydraulic parts |

| 306 | AP2D25(DH55 MAIN PUMP) Hydraulic parts |

| 307 | AP2D36/ZAX70 (MAIN PUMP) Hydraulic parts |

| SAUER CZPT SERIES | |

| 308 | PV20 Hydraulic parts |

| 309 | PV21(PVD21) Hydraulic parts |

| 310 | PV22 Hydraulic parts |

| 311 | PVD22 Hydraulic parts |

| 312 | 359.PV23(PVD23) Hydraulic parts |

| 313 | 360.PV24 Hydraulic parts |

| 314 | 361.SPV6/119 Hydraulic parts |

| 315 | 362.PV25 Hydraulic parts |

| 316 | 363.PV26 Hydraulic parts |

| 317 | 364.PV112 Hydraulic parts |

| 318 | 365.OPV27 Hydraulic parts |

| SAUER CZPT 90 SERIES | |

| 319 | PV90R030 Hydraulic parts |

| 320 | PV90R042 Hydraulic parts |

| 321 | PV90R55 Hydraulic parts |

| 322 | PV90R75 Hydraulic parts |

| 323 | PV90R100 Hydraulic parts |

| 324 | BRL100 Hydraulic parts |

| 325 | PV90R130 Hydraulic parts |

| 326 | PV90R180 Hydraulic parts |

| 327 | PV90R250 Hydraulic parts |

| 328 | SPV14 Hydraulic parts |

| 329 | SPV15 Hydraulic parts |

| 330 | SPV18 Hydraulic parts |

| 331 | MMFO25C Hydraulic parts |

| 332 | MPT044 Hydraulic parts |

| 333 | M44 Hydraulic parts |

| 334 | HRR057 Hydraulic parts |

| EATON SERIES | |

| 335 | 3321/3331(EATON 006) Hydraulic parts |

| 336 | EATON3322 Hydraulic parts |

| 337 | 4621/4631-007(EATON4621-007) Hydraulic parts |

| 338 | 5421/5431(EATON 23) Hydraulic parts |

| 339 | CASE1460 Hydraulic parts |

| 340 | CASE CS05A Hydraulic parts |

| 341 | EATON 3932-243 Hydraulic parts |

| 342 | EATON 6423 Hydraulic parts |

| 343 | 7621(EATON 24-7620) Hydraulic parts |

| 344 | EATON 78462 Hydraulic parts |

| EATON-VICKERS SERIES | |

| 345 | PVE19 Hydraulic parts |

| 346 | TA19 Hydraulic parts |

| 347 | PVE21 Hydraulic parts |

| 348 | PVH45 Hydraulic parts |

| 349 | PVH57 Hydraulic parts |

| 350 | PVH74 Hydraulic parts |

| 351 | PVH81 Hydraulic parts |

| 352 | PVH98 Hydraulic parts |

| 353 | PVH106(HPN-1398) Hydraulic parts |

| 354 | PVH131 Hydraulic parts |

| 355 | PVH141 Hydraulic parts |

| 356 | PVB5 Hydraulic parts |

| 357 | PVB6 Hydraulic parts |

| 358 | PVB10 Hydraulic parts |

| 359 | PVB15(PVQ32) Hydraulic parts |

| 360 | PVB20 Hydraulic parts |

| 361 | PVB29 Hydraulic parts |

| 362 | PVBQA29-SR Hydraulic parts |

| 363 | PVQ40/50 Hydraulic parts |

| 364 | PVB110 Hydraulic parts |

| 365 | TB35 Hydraulic parts |

| 366 | TB45 Hydraulic parts |

| LINDE SERIES | |

| 367 | HPV55T Hydraulic parts |

| 368 | HPR75 Hydraulic parts |

| 369 | HPR100 Hydraulic parts |

| 370 | HPR105 Hydraulic parts |

| 371 | HPR130 Hydraulic parts |

| 372 | HMR135 Hydraulic parts |

| 373 | HPR160 Hydraulic parts |

| 374 | LINDE 160 Hydraulic parts |

| 375 | B2PV35 Hydraulic parts |

| 376 | B2PV50(BPR50) Hydraulic parts |

| 377 | B2PV75(BPR75) Hydraulic parts |

| 378 | B2PV105(BPR105) Hydraulic parts |

| 379 | B2PV140 Hydraulic parts |

| 380 | BPV35 Hydraulic parts |

| 381 | BPV50 Hydraulic parts |

| 382 | BPV70 Hydraulic parts |

| 383 | BPV100 Hydraulic parts |

| 384 | BMV75.27 Hydraulic parts |

| 385 | BPR140 Hydraulic parts |

| 386 | BPR186 Hydraulic parts |

| 387 | BPR260 Hydraulic parts |

| 388 | BMF50 Hydraulic parts |

| 389 | BMF75 Hydraulic parts |

| 390 | BMF105 Hydraulic parts |

| PARKER SERIES | |

| 391 | VOLVO Hydraulic parts |

| 392 | F11-005 Hydraulic parts |

| 393 | F11-571 Hydraulic parts |

| 394 | F11-571 Hydraulic parts |

| 395 | F11-28 Hydraulic parts |

| 396 | F11-39 Hydraulic parts |

| 397 | F11-58 Hydraulic parts |

| 398 | F12-060 Hydraulic parts |

| 399 | F12-080 / F12-090 Hydraulic parts |

| 400 | F12-110-MF-1H Hydraulic parts |

| 401 | F11-150 Hydraulic parts |

| 402 | F11-250 Hydraulic parts |

| 403 | PVXS130 Hydraulic parts |

| 404 | PVXS180 Hydraulic parts |

| 405 | PVXS250 Hydraulic parts |

| 406 | PVSO250 Hydraulic parts |

| 407 | PV180 Hydraulic parts |

| 408 | PV250 Hydraulic parts |

| 409 | PLV250 Hydraulic parts |

| 410 | PVM-018 Hydraulic parts |

| 411 | PVM-571 Hydraulic parts |

| 412 | BMHQ30/PV180 Hydraulic parts |

| 413 | PAVC38 Hydraulic parts |

| 414 | PAVC65 Hydraulic parts |

| 415 | PAVC100 Hydraulic parts |

| 416 | PARKER 2145/P2145 Hydraulic parts |

| 417 | PARKER23 Hydraulic parts |

| 418 | PZ075 Hydraulic parts |

| 419 | PARKER 270/PV270 Hydraulic parts |

| 420 | PVP76 Hydraulic parts |

| 421 | PV29 PARKER-DANISION Hydraulic parts |

| 422 | PV0087 Hydraulic parts |

| 423 | P76 Hydraulic parts |

| 424 | PVG130B Hydraulic parts |

| 425 | PSV450 Hydraulic parts |

| 426 | PSV600 Hydraulic parts |

| 427 | PVT38 Hydraulic parts |

| 428 | PVT38 NEW DESIGN Hydraulic parts |

| 429 | PVT64 Hydraulic parts |

| 430 | PK100 Hydraulic parts |

| 431 | PMT14/18 Hydraulic parts |

| 432 | P080 Hydraulic parts |

| 433 | P2105 Hydraulic parts |

| 434 | P2060 Hydraulic parts |

| 435 | PVT38 Hydraulic parts |

| 436 | BZ732-100 Hydraulic parts |

| 437 | SH5V/131 Hydraulic parts |

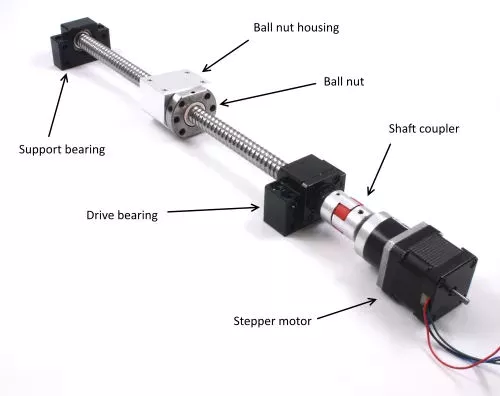

Supporting Ball Screws

In order to use a ball screw in a project, it is important to support it for rotation. Typically, this requires holding brackets and roller bearings. Longer screws may require bending or critical speed restraints. End machining may be necessary to fit the screw into the bearing. Connection to a motor requires coupling and appropriate machining. Tables or support rails may be necessary to restrain the nut.

Cost

In this report, you’ll get an in-depth analysis of the ball screw market. You’ll learn about the competitive landscape, product portfolio, and growth prospects across regions. The report will also include information on the market’s various drivers and restraints, as well as the factors driving or restraining its development. You’ll also get an in-depth look at the value chain and PEST analysis, which are important components of a market study.

One resource that you can use to research the Ball Screw market is CZPT. This website contains a database of authentic Indian manufacturers, suppliers, and importers. You’ll find contact details and email addresses of the companies, including those that produce a wide variety of different types of ball screws. CZPT even allows you to search by product category. That way, you can find a supplier based on the type of ball screw you need at the lowest price.

Another benefit of ball screws is their ability to operate in very delicate applications. In electric vehicles, they are often used to replace a common hydraulic system. They are also used to control gates at hydroelectric stations. You can also find them in motorised inspection tables, step photolithography machines, and microscopic integrated circuits. You can find hundreds of different ball screw designs, and you can even purchase them with nuts, wipers, and CZPT. Ball screws have several bearing balls, which help transfer load between nut and screw. They can be available with adjustable preload and non-preloaded options. And they’re manufactured to industry standards to meet the demands of their users.

If you’re looking for a reliable, high-performing screw, you’ll want to opt for a ball screw. These have high performance-to-cost ratios. You’ll need to choose between a lead screw and a ball screw, but both are reliable and efficient. Besides, the former is less expensive and offers great design flexibility. They’re corrosion-resistant and can even be self-locking for vertical applications.

Applications

A ball screw and nut assembly are essential components of a variety of important actuation and control devices. The 2 components rely on the ability of the screw to rotate easily while converting the rotation into precise lateral movement. Ball screws are a common component in computer-controlled motion-control systems. The precision of ball screw rotation is essential for the accurate adjustment of flight control surfaces. In addition, ball screws are important components of wire bonding and computer-controlled motion-control systems.

Ball screws are highly accurate, requiring minimal lead error. The lead error of a screw is the difference between the theoretical and actual distance traveled by the nut during rotation. The lead error of a ball screw depends on several factors, including the manufacturing accuracy of the ball grooves, the compactness of the assembly, and the set-up precision. This error is not constant from lead to lead, but it may be reduced through preloading, lubrication, and increased mounting accuracy.

The ball is urged to move up and down by rotation of the nut, which is preferably a hexagonal shaft. This allows the ball to be raised easily over the land of the screw. It is important to note that the nut has a groove on the outer surface that is deep enough to accommodate a ball. This groove is deep enough to accommodate a ball, and the groove extends the length of the screw, thereby reducing friction and increasing precision.

The recirculated balls in a multi-start ball screw assembly may cross multiple threads and turn in the circuit. Multi-start ball screw assemblies typically use the internal channel method to recirculate balls. This design allows multiple ball nuts to be used in a single nut and can be easily installed. The ball nut and the nut may also be incorporated into several separate circuits. If several recirculation paths are desired, a ball nut and a multi-start system may be used.

Durability

A key feature of ball screws is their durability. During manufacture, a ball screw’s material must be chosen carefully. A corrosion-resistant steel called Cronidur(r) 30 is an ideal choice. Ball screws made from this material are exceptionally reliable in space due to their alternating steel-ceramic architecture. As the conditions of space are extreme, corrosion-resistant materials are essential to ensure optimum performance. CZPT has decades of experience manufacturing high-quality ball screws. Besides providing a complete range of ball screws, the company also offers technological solutions and dedicated components.

CZPT developed a special design for the High-Durability Precision Ball Screw. This design makes it easier to form a thin film of oil on the material’s surface. This oil helps reduce friction and improve the precision of a ball screw. This material’s special microstructure reduces the wear of ball screws and improves their service life. CZPT also aims to improve the wear-resistance of ball screws.

In addition to the axial load, a ball screw’s life rating should be based on the jacking and vertical loads. In other words, if all load balls are in contact with the raceways, the L-10 life rating of ball screw assemblies would be converted to an L-2 life rating. This change would increase the overall reliability of a ball screw to 98%. Then again, it’s important to note that vertical load is the only 1 that would be completely removed from the chart.

In addition to these important considerations, it is essential to operate ball screws within their recommended operating temperature range. Failure to do so could result in thermal expansion of the ball screw, causing positioning errors. To ensure lubrication of the ball screw, it’s important to keep its operating temperature within the recommended range. However, it is possible to operate it at temperatures that are too high. If this occurs, the screw should be sent to the manufacturer for repair.

Size

Besides their obvious use, ball screws come in 2 sizes, large and small. Although small balls should not show significant wear, they should still be used to enhance the screw’s durability. This can be difficult to determine because screw rebuilders tend to overlook this aspect. So, what is the best size for ball screws? This article will look at both sizes and what they mean for the screw’s durability. Also, we’ll look at some of the things to keep in mind when choosing the right size for your project.

A ball screw’s size depends on its application and performance requirements. Some types have small diameters and fine leads, while others feature large diameters. High precision applications often require miniature ball screws. Some manufacturers even offer compact ball screws with a smaller outer diameter. The latter is commonly found in miniature designs and feature diameters up to 25 mm. However, this doesn’t mean that a smaller diameter means less accuracy. Regardless of the size, you’ll want to make sure to select a screw that will meet your requirements.

The screw’s root diameter is a critical measurement in determining critical speed and column load calculations. A ball screw’s minor diameter is the minimum dimension of the screw shaft at the bottom of the ball grooves. In addition, the idler ball is a necessary component of a ball screw. It prevents friction between the load and idler balls, but does not carry the load itself. Likewise, the non-operating load capacity should be large enough to prevent the balls from brinelling and plastic deformation.

The characteristic speed is the rotational speed at which the ball screw begins to vibrate due to dynamic load. Inch/imperial screws are specified for 1 million revolutions, while metric screw has a specific limit for 1 million inches of linear travel. Various manufacturing processes have their own ways to calculate the useful life of ball screw assemblies. For example, Precision Grinding produces the lowest lead errors. In addition, the life of a ball screw depends on the length of the screw and the mounting support for the end bearings.

Maintenance

It is critical to regularly perform PM on your ball screw assemblies to ensure optimal performance. A dirty ball screw assembly will result in poor performance and faster wear, so removing dirt from the nut and shaft is a good idea. If there are problems with the ball nut, the lubricant inside can become stripped or the nut can become dirty due to chemical exposure. You should also check for oxidation or corrosion on the contact surfaces of the ball screw, and replace it if necessary.

The first sign of a deteriorating ball screw is excessive vibration. This may be caused by a bent screw shaft or misaligned bearing housings. If it makes noise when running, this may be due to excessive build-up or a broken return tube. Other issues may be caused by endplay in support bearings or excessive preload or improper lubrication. If any of these problems are found, it is essential to perform regular maintenance on the ball screw to prolong its life.

Getting regular maintenance on the ball screw assembly is important. If the screw is not properly maintained, it may wear out prematurely. If this happens, you can contact a ball screw repair service. CZPT International, Inc., a leading supplier of industrial parts, can help you get the screw back into optimal working order or find a new one. A ball screw repair company can help you avoid the inconvenience of downtime and maximize your productivity.

It is essential to properly lubricate a ball screw assembly in order to prolong its life. Lubrication can prevent corrosion and increase the life of the screw by 85 percent. It is important to remember that the type of lubricant you use should correspond to the load applied to the assembly. Lubrication should also be done at regular intervals. Once you’ve established the right amount of lubrication, you can then apply it on the screw.